Fill a Valid Pre Trip Inspection Checklist Form

Before embarking on any journey, especially in the realm of commercial driving, a thorough examination of the vehicle is not just advisable; it is essential. The Pre Trip Inspection Checklist serves as a critical tool for ensuring safety and compliance on the road. This checklist encompasses various aspects of vehicle readiness, including an assessment of the exterior, interior, and mechanical components. Drivers are prompted to check the tires for proper inflation and tread depth, ensuring optimal traction and stability. The lights, signals, and brakes must be inspected to confirm they are functioning correctly, as these elements are vital for safe navigation. Additionally, the checklist encourages a review of the fluid levels, such as oil and coolant, to prevent any potential breakdowns during transit. By systematically addressing these areas, drivers not only safeguard their own well-being but also contribute to the safety of others on the road. This proactive approach fosters a culture of responsibility and diligence, underscoring the importance of preparation in the transportation industry.

Additional PDF Templates

How to Design a Crest - A symbol of heritage and identity, often reflecting the history of a family.

To further understand the process of requesting a sales tax refund in Georgia, you may want to review the information provided at https://georgiapdf.com/st-12b-georgia, which offers guidance on completing the ST-12B Georgia form effectively.

Hiv Normal Range - Agencies must enter their name, address, and CLIA number on the form.

Free Printable Puppy Health Guarantee Template - Any potential legal disputes will be resolved in Schuyler County, Missouri.

Similar forms

- Vehicle Maintenance Log: This document tracks routine maintenance and repairs performed on a vehicle, ensuring it remains in safe operating condition. Like the Pre Trip Inspection Checklist, it emphasizes the importance of regular checks to prevent mechanical failures.

- Daily Vehicle Inspection Report: Similar to the Pre Trip Inspection Checklist, this report is filled out by drivers at the beginning of each day. It details the condition of various vehicle components and highlights any issues that need immediate attention.

- Safety Inspection Report: Conducted periodically, this report assesses a vehicle's compliance with safety regulations. It shares a common goal with the Pre Trip Inspection Checklist: to ensure that the vehicle is safe for operation.

- Driver's Daily Log: This document records a driver's hours of service and rest breaks. While its primary focus is on compliance with regulations, it also reinforces the importance of vehicle readiness, akin to the Pre Trip Inspection Checklist.

- Accident Report Form: After an incident, this form documents the details surrounding the event. Both it and the Pre Trip Inspection Checklist aim to promote safety, albeit from different perspectives—one focuses on prevention, while the other addresses consequences.

- Fuel Consumption Log: This log tracks fuel usage and efficiency. Like the Pre Trip Inspection Checklist, it encourages careful monitoring of vehicle performance, which can help identify potential issues early.

- Maintenance Request Form: When issues are identified, this form is used to request repairs. It is similar to the Pre Trip Inspection Checklist in that both documents aim to ensure the vehicle is operating safely and effectively.

- Arizona Trailer Bill of Sale: This form is essential for documenting the sale of a trailer in Arizona, ensuring both parties have proper proof of the transaction for registration. To finalize your trailer sale legally, download the form now.

- Inspection Sticker: This sticker indicates that a vehicle has passed a safety inspection. Both the sticker and the Pre Trip Inspection Checklist serve as assurances of safety and compliance with regulations.

- Vehicle Registration Document: While primarily a legal document, it includes essential information about the vehicle. Like the Pre Trip Inspection Checklist, it is crucial for ensuring that the vehicle is authorized for use on public roads.

- Emergency Equipment Checklist: This checklist ensures that all necessary emergency equipment is present in a vehicle. Similar to the Pre Trip Inspection Checklist, it focuses on preparedness and safety for unexpected situations.

Document Example

Class A CDL

®

®

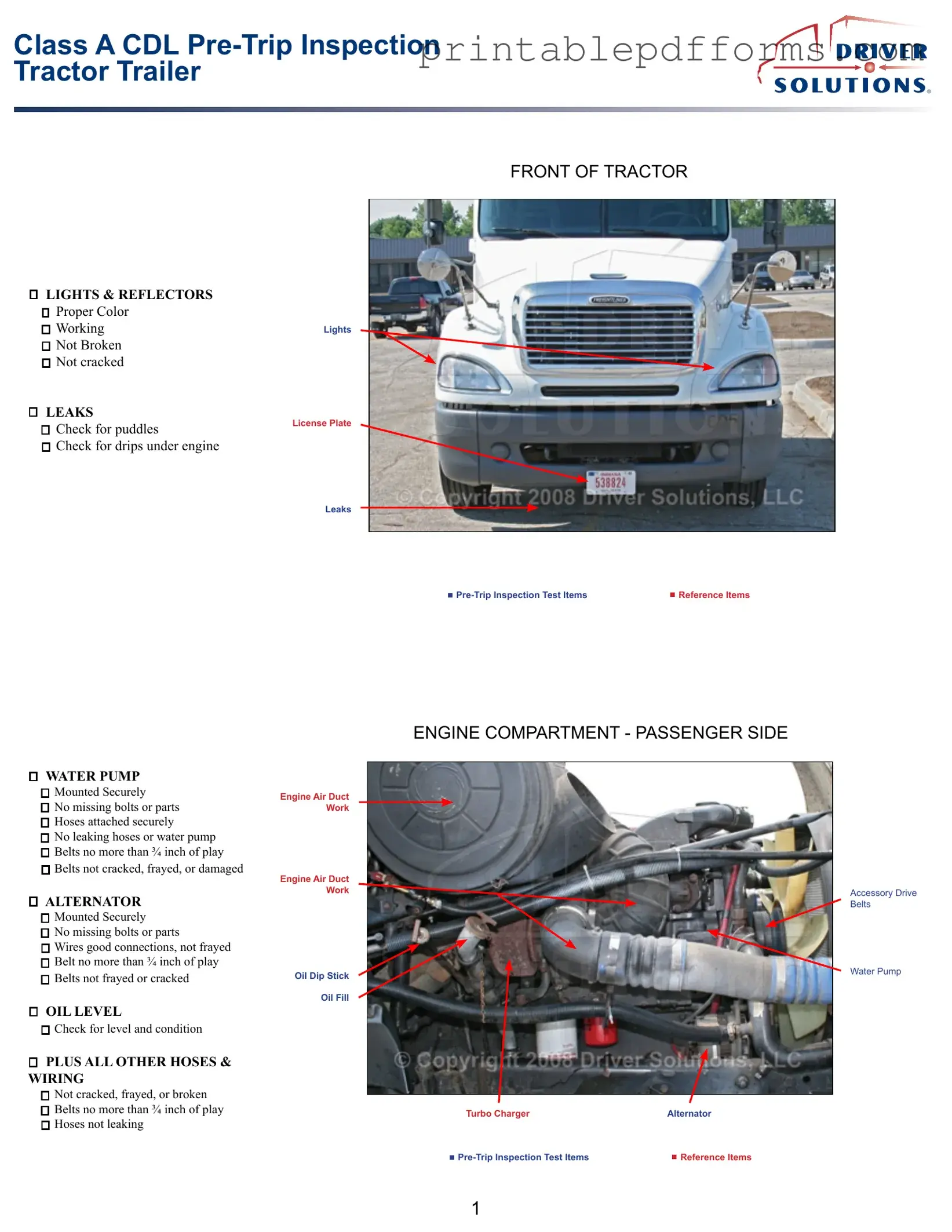

FRONT OF TRACTOR

LIGHTS & REFLECTORS o Proper Color

o Working

o Not Broken o Not cracked

LEAKS

o Check for puddles

o Check for drips under engine

Lights

License Plate

Leaks

Reference Items |

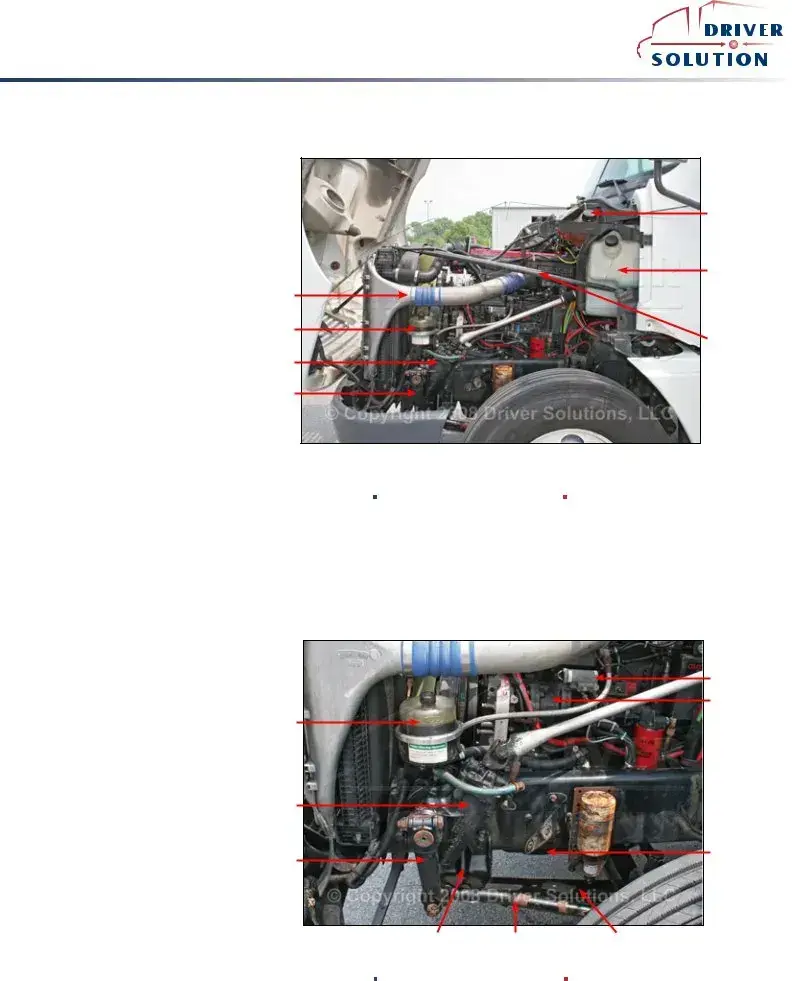

ENGINE COMPARTMENT - PASSENGER SIDE

WATER PUMP o Mounted Securely

o No missing bolts or parts o Hoses attached securely

o No leaking hoses or water pump o Belts no more than ¾ inch of play

o Belts not cracked, frayed, or damaged

ALTERNATOR

o Mounted Securely

o No missing bolts or parts

oWires good connections, not frayed

oBelt no more than ¾ inch of play

oBelts not frayed or cracked

OIL LEVEL

oCheck for level and condition

PLUS ALL OTHER HOSES & WIRING

oNot cracked, frayed, or broken

oBelts no more than ¾ inch of play o Hoses not leaking

Engine Air Duct Work

Engine Air Duct Work

Oil Dip Stick

Oil Fill

|

Accessory Drive |

|

Belts |

|

Water Pump |

Turbo Charger |

Alternator |

Reference Items |

1

Class A CDL

®

®

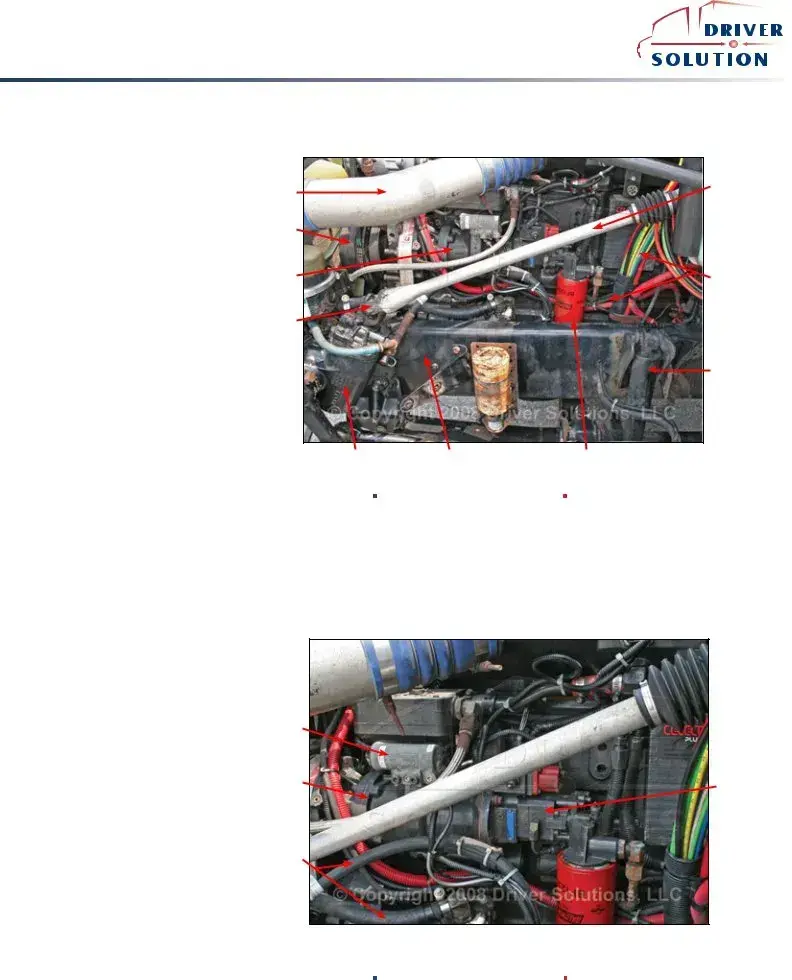

ENGINE COMPARTMENT - DRIVER SIDE

COOLANT

oCheck for level and condition

oHoses attached and not leaking

POWER STEERING RESERVOIR

oMounted properly

oHoses attached and not leaking

oCheck for level and condition

AIR COMPRESSOR

oMounted Securely

oNo missing bolts or parts

oNo air leaks at lines

oCheck if gear or belt driven

oBelt no more than ¾ inch of play

oBelts not cracked or frayed

STEERING GEAR BOX

oMounted properly

oNo missing parts, nuts or bolts o Lines and hoses not leaking or broken

|

Engine Coolant |

|

Reservoir |

|

Windsheild |

|

Washer Fluid |

|

Reservoir |

Engine Air Duct |

|

Work |

|

Power Steering |

|

Reservoir |

Radiator Brace |

|

|

Steering Gear |

|

Box |

|

Pitman Arm |

|

Reference Items |

POWER STEERING RESERVOIR |

ENGINE COMPARTMENT - DRIVER SIDE CON’T |

||

|

|

|

|

o Mounted properly |

|

|

|

o Hoses attached and not leaking |

|

|

|

o Check for level and condition |

|

|

|

AIR COMPRESSOR |

|

|

|

o Mounted Securely |

Power Steering |

|

|

o No missing bolts or parts |

|

|

|

Reservoir |

|

|

|

o No air leaks at lines |

|

|

|

o Check if gear or belt driven |

|

|

|

o Belt no more than ¾ inch of play |

|

|

|

o Belts not cracked or frayed |

|

|

|

STEERING GEAR BOX |

Steering Gear |

|

|

Box |

|

|

|

o Mounted properly |

|

|

|

o No missing parts, nuts or bolts |

|

|

|

o Lines and hoses not leaking or |

Pitman Arm |

|

|

broken |

|

|

|

|

|

|

|

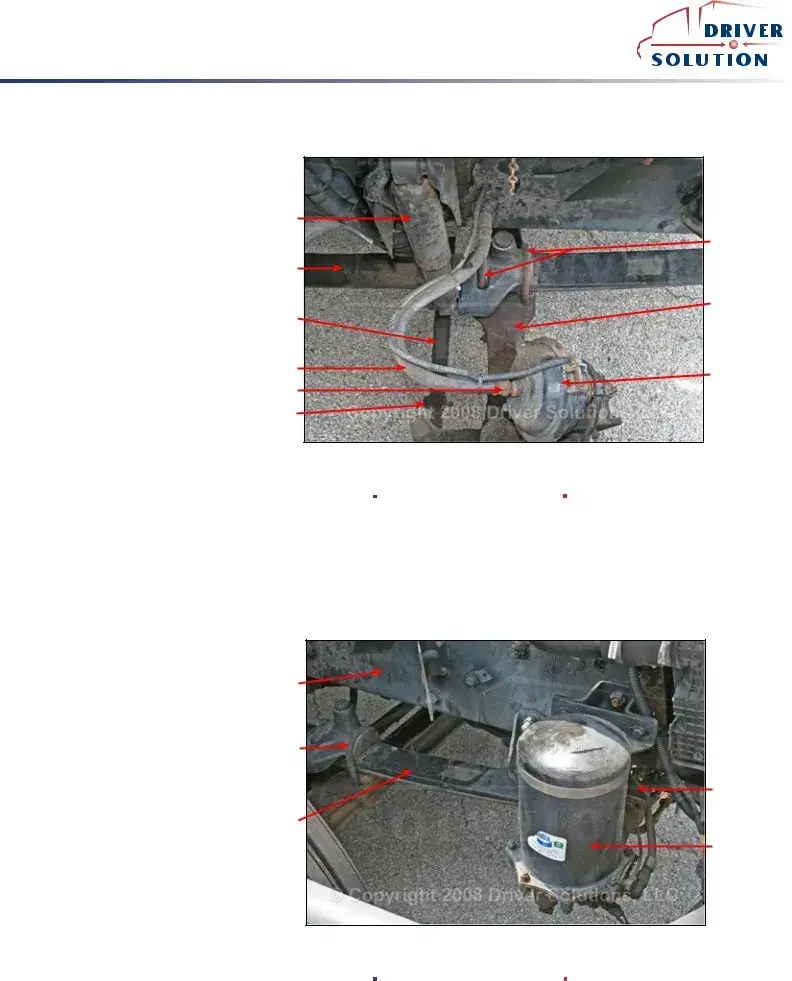

STEERING LINKAGE |

|

|

|

o Pitman arm, Drag link, Steering |

|

|

|

knuckle, Tie rods and tie rod ends |

|

|

|

o Not cracked, bent or broken |

Spring Mount |

Drag Link |

Leaf Spring |

o Castle nuts and cotter pins |

|

|

|

o Not missing and in place |

|

|

|

Reference Items |

Air Governor

Air Compressor

Engine Oil Pan

2

Class A CDL

®

®

AIR COMPRESSOR o Mounted Securely

o No missing bolts or parts o No air leaks at lines

o Check if gear or belt driven

o Belt no more than ¾ inch of play o Belts not cracked or frayed

STEERING GEAR BOX

o Mounted properly

oNo missing parts, nuts or bolts o Lines and hoses not leaking or broken

ENGINE COMPARTMENT - DRIVER SIDE CON’T

Engine Air Duct

Work

Fan Belts

Gear Driven Air

Compressor

Steering

Steering Column

Additional Hoses & Wiring

Shock Absorber

Steering Gear Box |

Frame Rail |

Fuel Filter |

Reference Items |

||

ENGINE COMPARTMENT - AIR COMPRESSOR

AIR COMPRESSOR o Mounted Securely

o No missing bolts or parts o No air leaks at lines

o Check if gear or belt driven

o Belt no more than ¾ inch of play o Belts not cracked or frayed

Air Governor

Gear Driven Air Compressor

Hoses

Fuel Pump

Reference Items |

3

Class A CDL

®

®

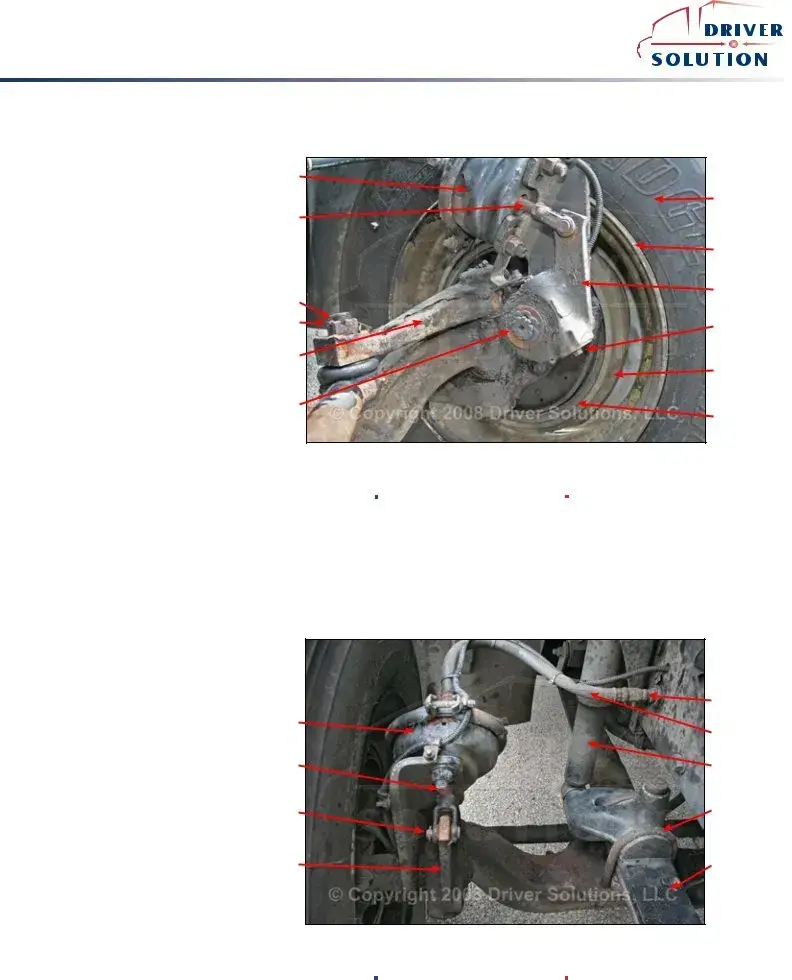

FRONT SUSPENSION

LEAF SPRINGS

o Not shifted or out of place

oNot cracked, broken or missing

SPRING MOUNTS

oMounted securely- front, back, and

oNot cracked or broken

SHOCK ABSORBER

oMounted Securely

oNot bent or dented o Not leaking

Shock Absorber

Leaf Spring

Tie Rod

Air Hose

Air LIne

Tie Rod End

Axle |

Service Brake |

Chamber |

Reference Items |

LEAF SPRINGS

o Not shifted or out of place

oNot cracked, broken or missing

SPRING MOUNTS

oMounted securely- front, back, and

oNot cracked or broken

SHOCK ABSORBER

oMounted Securely

oNot bent or dented o Not leaking

FRONT SUSPENSION CON’T

Frame Rail

Leaf Spring

Air Dryer location varies depending on model.

Located either behind the front bumper or behind the fuel tank.

Reference Items |

4

Spring Mount

Air Dryer

Class A CDL

®

®

HOSES AND LINES |

|

FRONT BRAKES |

|

|

|

||

o Mounted securely |

Service Brake |

|

|

o |

Not leaking |

|

|

o |

Not cracked or frayed |

Chamber |

|

|

Tire |

||

|

|

|

|

CHAMBER |

Push Rod |

|

|

o Mounted securely |

|

|

|

o Not dented or damaged |

|

Wheel |

|

o |

Not leaking |

|

|

SLACK ADJUSTER |

|

Slack Adjuster |

|

o |

No more than 1 inch of free play at |

Castle Nut |

|

the push rod with the brakes released. |

Cotter Pin |

Adjustment Nut |

|

o |

Not bent, broken, loose, or missing |

|

|

|

|

||

parts |

Steering |

|

|

|

|

Knuckle |

Brake Drum |

DRUMS |

|

||

|

|

||

o |

Not cracked, broken or dented |

|

|

o |

No oil leaking from inner oil seal, |

Snap Ring |

|

free of debris |

|

Brake Lining |

|

LININGS |

|

|

|

oNo cracked, broken or missing parts o Not less than ¼ inch in thickness

Reference Items |

HOSES AND LINES o Mounted securely o Not leaking

o Not cracked or frayed

CHAMBER

o Mounted securely

oNot dented or damaged

oNot leaking

SLACK ADJUSTER

oNo more than 1 inch of free play at the push rod with the brakes released.

oNot bent, broken, loose, or missing parts

DRUMS

oNot cracked, broken or dented

oNo oil leaking from inner oil seal, free of debris

LININGS

oNo cracked, broken or missing parts

oNot less than ¼ inch in thickness

FRONT BRAKES CON’T

Service Brake

Chamber

Push Rod

Clevis Pin &

Cotter Pin

Slack Adjuster

Reference Items |

Air Line

Air Hose

Shock Absorber

Spring

5

Class A CDL

®

®

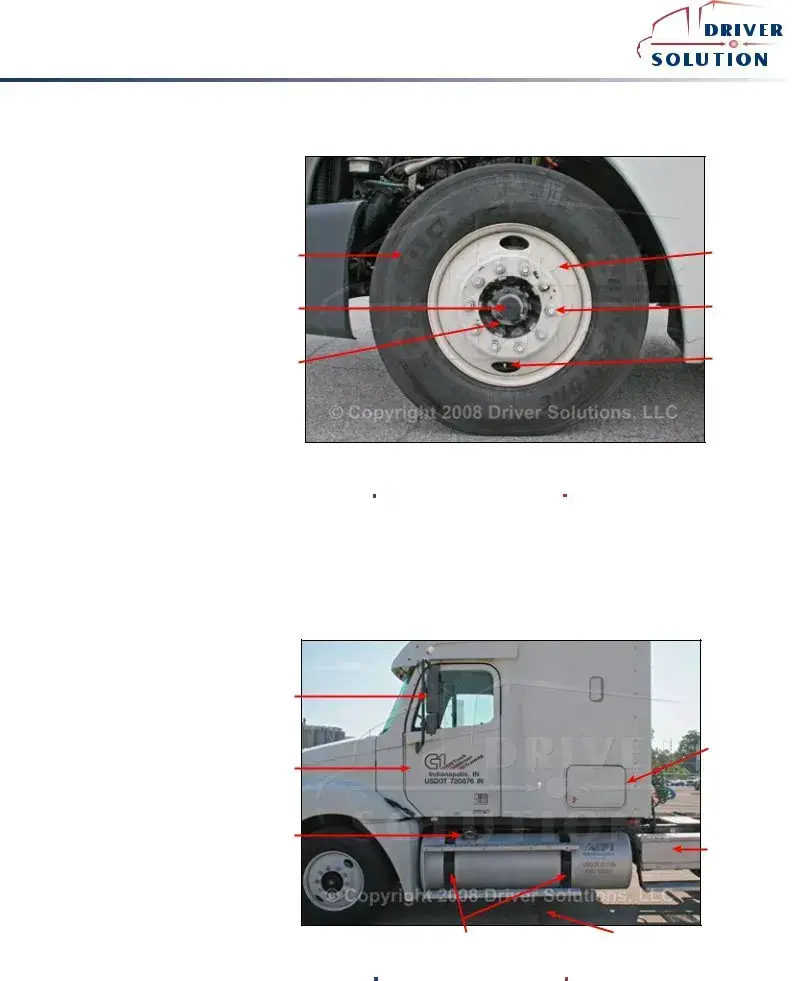

FRONT WHEEL

TIRES

oProper inflation – company or manufacturer specification

o No bulges, cuts, or retreads

o Minimum tread depth of 4/32”

RIMS

oNot bent, cracked, No welding repairs.

LUG NUTS

oNone are missing

oTight – no shinny threads, or rust trails

OUTER HUB OIL SEALS

oNot leaking, no missing bolts o Proper oil level

Tire |

Wheel |

|

Hub Oil |

Lug Nut |

|

Reservior |

||

|

||

Outer Hub |

Valve Cap |

|

Oil Seal |

|

Reference Items |

DRIVER FUEL AREA

DRIVER’S DOOR

oDoor opens and closes properly

oSeal is in good condition

DRIVER’S MIRRORS

oClean and free of obstruction

oNot cracked, broken, or damaged

oMounted securely

FUEL TANK

oMounted securely

o Not leaking

o Seal in cap OK

Mirror |

Storage |

Compartment |

Door |

Cap & Seal |

Battery Box & |

Cover |

Saddle Mounts |

Leaks |

Reference Items |

6

Class A CDL

®

®

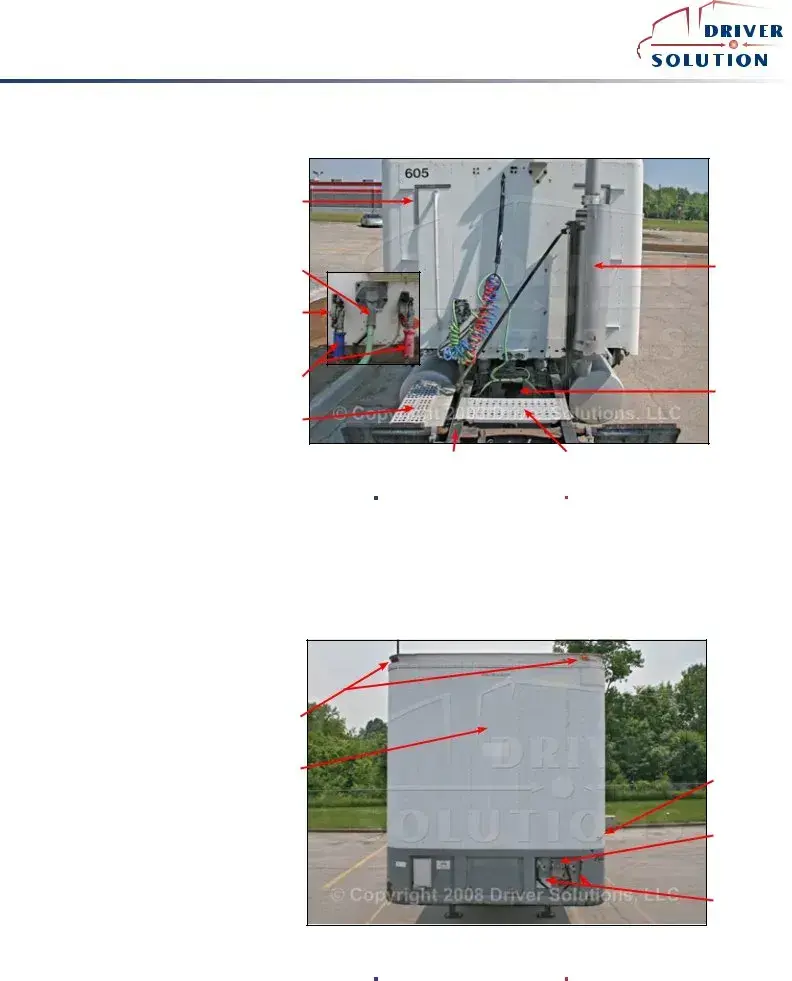

AIR LINES & ELECTRIC LINE o Not cracked, frayed, cut, or kinked o Mounted securely at the glad hands o Not leaking

BEHIND THE CAB

BATTERY BOX & BATTERIES o Box is mounted properly

o Batteries are secure in the box o Lid secure

o Connections not corroded

CATWALK

o Mounted properly

oNot, missing, or damaged

oFree of obstructions

DRIVE SHAFT

oNot bent, or damaged

oCoupling,

EXHAUST SYSTEM

oSecurely mounted

oNot dented or damaged

oNot leaking

FRAME

oNot cracked, or damaged

oNo missing bolts

oNo illegal welds

LIGHTS & REFLECTORS

oClean and working

Lights & |

|

Reflectors |

|

Electrical Line |

Exhaust |

Glad Hand |

|

Service & |

|

Emergency |

|

Airlines |

Drive Shaft |

|

|

Battery Box & |

|

Batteries |

|

Frame |

Catwalk |

Reference Items |

FRONT OF TRAILER

HEADER BOARD

oNo holes or missing rivets

LIGHTS & REFLECTORS

oNone broken, cracked, or missing

oWorking and proper color of amber

Lights |

Header Board |

Height Sticker

Electric Hookup

Air Line

Reference Items |

7

Class A CDL

®

®

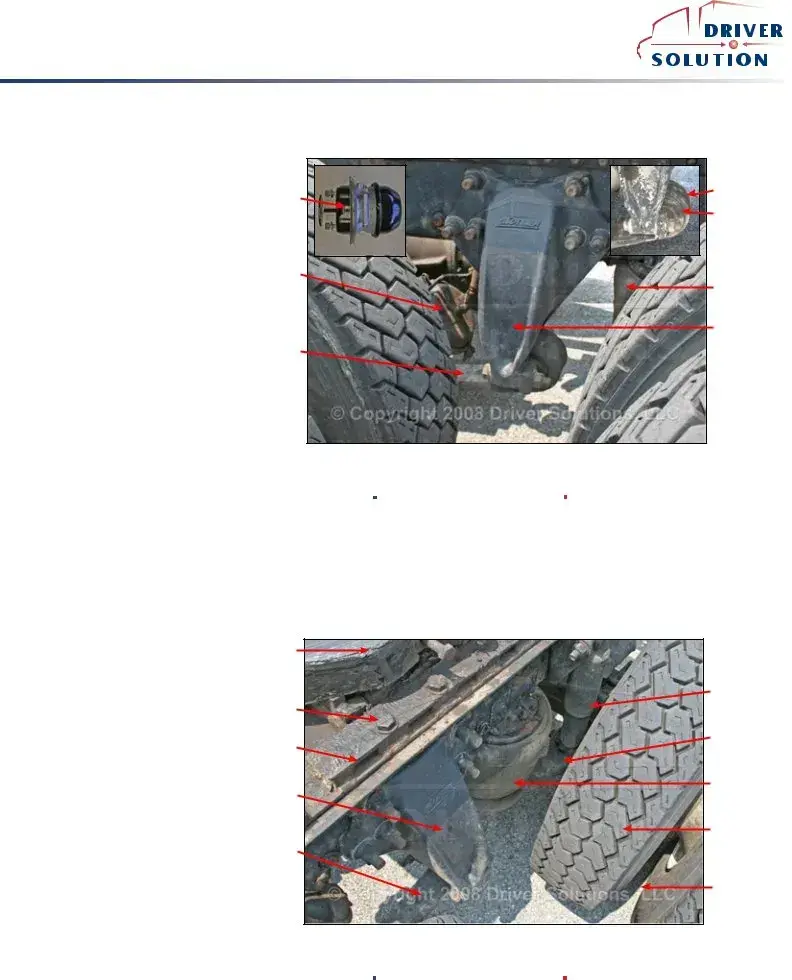

DRIVE AXLE SUSPENSION

CONTROL ARM MOUNT o Mounted securely

o Not bent, broken or damaged

CONTROLARM

oMounted securely – front, back, and

o Not cracked, or broken

SHOCK ABSORBER

o Mounted Securely

oNot bent, dented or leaking

TORSION BAR

oMounted Securely

oNot bent, broken or damaged

AIR BAGS

oMounted Securely

o Not leaking

Spring Brake |

Torsion Bar |

|

|

Chamber |

Control Arm |

|

|

Spring Brake |

|

Chamber |

Air Bag |

|

|

|

Control Arm |

|

Mount |

Control Arm |

|

Reference Items |

DRIVE AXLE SUSPENSION CON’T & FIFTH WHEEL

CONTROL ARM MOUNT o Mounted securely

o Not bent, broken or damaged

CONTROLARM

oMounted securely – front, back, and

o Not cracked, or broken

SHOCK ABSORBER

o Mounted Securely

oNot bent, dented or leaking

TORSION BAR

oMounted Securely

oNot bent, broken or damaged

AIR BAGS

oMounted Securely

o Not leaking

Skid Plate |

|

|

Shock Absorber |

Mounting |

|

Bolts |

|

Locking |

Spring |

|

|

Pins |

|

Control Arm |

Air Bag |

|

|

Mount |

|

|

Tire |

Control Arm |

|

|

Space |

Reference Items |

8

Class A CDL

®

®

HOSES AND LINES o Mounted securely o Not leaking

o Not cracked or frayed

CHAMBER

o Mounted securely

oNot dented or damaged

oNot leaking

SLACK ADJUSTER

oNo more than 1 inch of free play at the push rod with the brakes released.

oNo bent, broken, loose, or missing parts

DRUMS

oNot cracked, broken or dented

oNo oil leaking from inner oil seal, free of debris

LININGS

oNo cracked, broken or missing parts

oNot less than ¼ inch in thickness

DRIVE BRAKES & DRIVE SHAFT

Drive Shaft

Universal Joint

Differential

Reference Items |

Air Line

Service Brake Chamber

Frame

Brake Chamber Mount

Slack Adjuster

TIRES

oProper inflation - company or manufacturer specification.

o No bulges or cuts, can have retreads o Minimum tread depth of 2/32”

RIMS

oNot bent or cracked

oNo welding repairs

LUG NUTS

oNone missing

oTight – no shinny threads, or rust trails

OUTER AXLE SEAL

oNot leaking, no missing bolts

SPACE OR SPACER

oCheck for objects between wheels

oCheck for proper spacing

Lug Nuts

Outer Axle Seal

DRIVE WHEELS

Tire

Bud Rim

Dayton Rim |

Spacer |

Reference Items |

9

Class A CDL

®

®

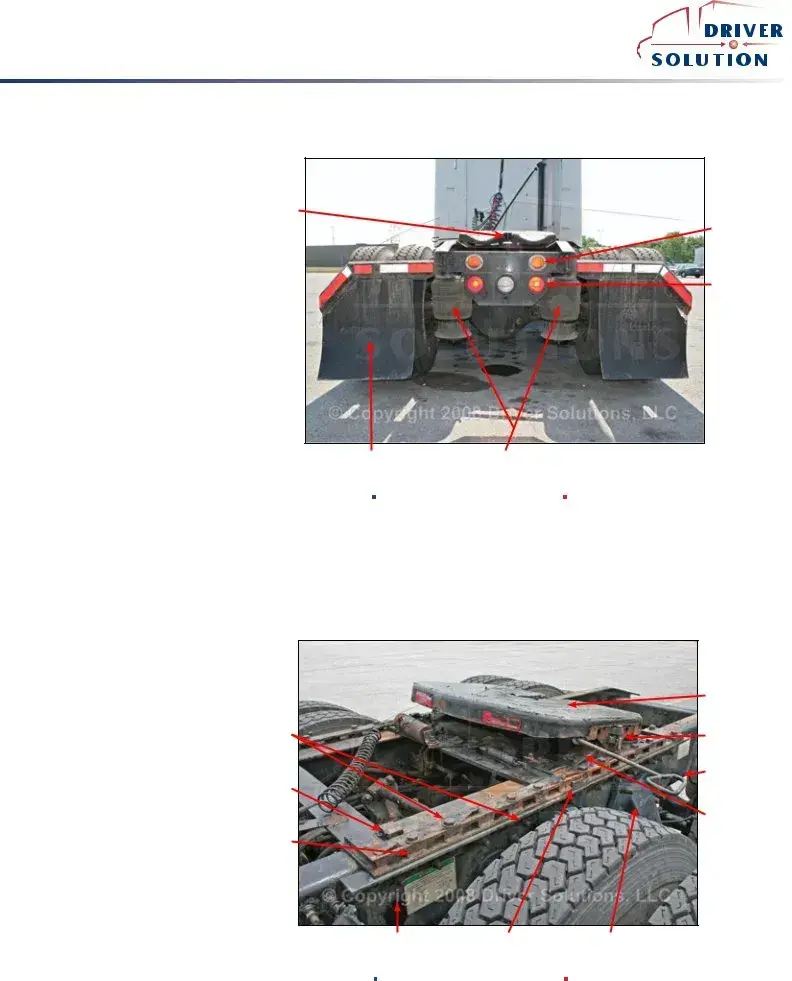

REAR OF TRACTOR

LIGHTS & REFLECTORS o Not cracked, or broken

o Working and proper color

SPLASH GUARDS

oNot missing or torn and properly mounted

Locking Jaws |

|

|

Reflectors |

|

Lights |

Splash Guard |

Air Bags |

Reference Items |

MOUNTING BOLTS

oNone missing or broken

RELEASE ARM

oNot bent, broken, or damaged

oEngaged in the lock position

LOCKING PINS

oNo missing or broken parts

oEngaged and locked

PLATFORM

oSecurely holds skid plate

oNot cracked, or broken

SKID PLATE

oMounted properly on the platform

oProperly greased

oTilting freely

Mounting Bolts

Slide Stops (all 4 corners)

COUPLING SYSTEM

Skid Plate |

Pivot Pin |

Release Arm |

Platform |

KING PIN |

Welds |

oNot broken, bent, or damaged

APRON

oNo bends or damage to visible portions

GAP

oCheck that the trailer apron is lying flat on the fifth wheel skid plate

Frame |

Slide Locking Pin |

Spring Mount |

JAWS |

Reference Items |

|

|

|

|

o Check that the locking jaws are fully |

|

|

closed around the shank of the king pin |

10 |

|

Form Specs

| Fact Name | Description |

|---|---|

| Purpose | The Pre Trip Inspection Checklist is designed to ensure that vehicles are safe and roadworthy before they are operated. It helps identify potential issues that could lead to accidents or breakdowns. |

| Components | The checklist typically includes items such as brakes, lights, tires, and fluid levels. Each component must be thoroughly inspected to ensure compliance with safety standards. |

| Frequency | Drivers are required to complete the checklist before each trip. This routine helps maintain vehicle safety and performance over time. |

| Governing Laws | In many states, including California and Texas, the use of a Pre Trip Inspection Checklist is mandated by state transportation regulations, which align with federal safety requirements. |

Crucial Questions on This Form

What is the purpose of the Pre Trip Inspection Checklist?

The Pre Trip Inspection Checklist is designed to ensure that a vehicle is safe and ready for operation before it hits the road. By completing this checklist, drivers can identify any potential issues that may affect the safety and performance of the vehicle. This proactive approach helps prevent accidents and breakdowns, contributing to the safety of both the driver and others on the road.

Who is responsible for completing the Pre Trip Inspection Checklist?

It is the responsibility of the driver to complete the Pre Trip Inspection Checklist. Drivers should take the time to thoroughly inspect their vehicle before starting their journey. This responsibility is crucial for ensuring the vehicle's safety and compliance with regulations.

What items should be included in the Pre Trip Inspection Checklist?

The checklist typically includes various items that need to be inspected. Common categories include:

- Exterior: Check for any visible damage, fluid leaks, or tire condition.

- Interior: Ensure that all controls are functioning properly and that the seatbelt is operational.

- Under the Hood: Inspect fluid levels, belts, and hoses for wear or damage.

- Brakes and Lights: Test the brakes and check all lights, including turn signals and hazard lights.

By covering these areas, drivers can identify issues that may require attention.

How often should the Pre Trip Inspection Checklist be completed?

The Pre Trip Inspection Checklist should be completed before every trip. This routine practice ensures that any changes or new issues are identified before the vehicle is used. Consistency in this process promotes safety and reliability.

What should a driver do if they find a problem during the inspection?

If a driver discovers a problem during the inspection, they should not operate the vehicle until the issue is resolved. It is essential to report the problem to a supervisor or a qualified mechanic. Addressing these issues promptly can prevent accidents and ensure the vehicle remains safe for use.

Is there a specific format for the Pre Trip Inspection Checklist?

The Pre Trip Inspection Checklist can vary by organization or regulatory requirements. However, it should be clear and easy to understand. Many organizations provide a standardized form to ensure that all necessary items are covered. Drivers should use the format provided by their employer or regulatory body.

What are the consequences of not completing the Pre Trip Inspection Checklist?

Failing to complete the Pre Trip Inspection Checklist can lead to serious consequences. These may include:

- Increased risk of accidents due to undetected vehicle issues.

- Legal repercussions for not adhering to safety regulations.

- Financial costs associated with accidents or breakdowns.

Ultimately, neglecting this important step can jeopardize the safety of the driver and others on the road.

Documents used along the form

When preparing for a trip, especially in a commercial or fleet context, several documents complement the Pre Trip Inspection Checklist. These documents ensure that all safety and operational aspects are covered, providing peace of mind to drivers and fleet managers alike. Below are some commonly used forms that work in conjunction with the checklist.

- Driver's Daily Log: This form records the hours of service for drivers, ensuring compliance with regulations regarding driving time and rest periods. It helps monitor fatigue levels and promotes safety on the road.

- Medical Power of Attorney Form: This form is essential for appointing someone to make health care decisions on your behalf if you are unable to do so yourself. Understanding its importance in health care planning is crucial for Ohio residents. For more details, refer to All Ohio Forms.

- Vehicle Maintenance Record: This document tracks all maintenance and repair activities performed on the vehicle. Keeping this record updated helps identify recurring issues and ensures that the vehicle remains in optimal working condition.

- Accident Report Form: In the event of an incident, this form is crucial for documenting details such as the time, location, and circumstances of the accident. Accurate reporting aids in insurance claims and legal matters.

- Fuel Purchase Log: This log records fuel purchases, including dates, amounts, and costs. It assists in tracking fuel expenses and analyzing fuel efficiency, which can help in budgeting and operational planning.

These documents, when used alongside the Pre Trip Inspection Checklist, create a comprehensive approach to vehicle safety and compliance. By maintaining these records, drivers and fleet operators can ensure that they are well-prepared for their journeys, ultimately enhancing safety and efficiency on the road.

Misconceptions

When it comes to the Pre Trip Inspection Checklist, many people have misunderstandings that can lead to confusion or improper use. Here are ten common misconceptions:

- It’s optional for drivers. Many believe that completing the checklist is not mandatory. However, it is a crucial step for safety and compliance.

- Only new drivers need to use it. Some think that experienced drivers can skip the checklist. In reality, every driver should perform this inspection, regardless of experience.

- It only covers the exterior of the vehicle. While the exterior is important, the checklist also includes interior checks, such as the functionality of lights and signals.

- It takes too much time. Many drivers feel that the inspection is time-consuming. However, a thorough check can often be completed in a reasonable amount of time and can prevent major issues later.

- It’s just a formality. Some view the checklist as a mere formality. In fact, it serves a vital purpose in ensuring vehicle safety and compliance with regulations.

- Once completed, it doesn’t need to be revisited. Some drivers think that once they fill out the checklist, it’s done for the day. Regular inspections should be part of every trip.

- It only needs to be done at the start of a trip. Many believe inspections are only necessary before starting a journey. However, checks should also be done during breaks and at the end of the trip.

- All vehicles have the same checklist. Some think that one standard checklist applies to all vehicles. In reality, checklists can vary based on vehicle type and size.

- It’s only for commercial drivers. While commercial drivers are required to use it, personal vehicle owners can also benefit from regular inspections.

- If nothing seems wrong, the checklist isn’t necessary. Many assume that if the vehicle appears fine, an inspection isn’t needed. However, hidden issues can exist that only a thorough check will reveal.

Understanding these misconceptions can help improve safety and compliance for all drivers. Regularly using the Pre Trip Inspection Checklist is a proactive step toward ensuring a safe driving experience.